Industrial Oil Water Separator

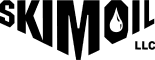

Fabricated Steel API design Oil Water Separators (OWS)

performance is 10 ppm or less, 30 micron oil droplet.

Oil/fuel removal 10 mg/L or less of oil droplets 30 micron and larger of non-emulsified, free and dispersed oils

Solids (TSS) 40 -100 mg/L

Influent concentration basis:

Oils 1250 mg/L or less influent loading

TSS 400 mg/L or less influent loading

SPECIFICATIONS

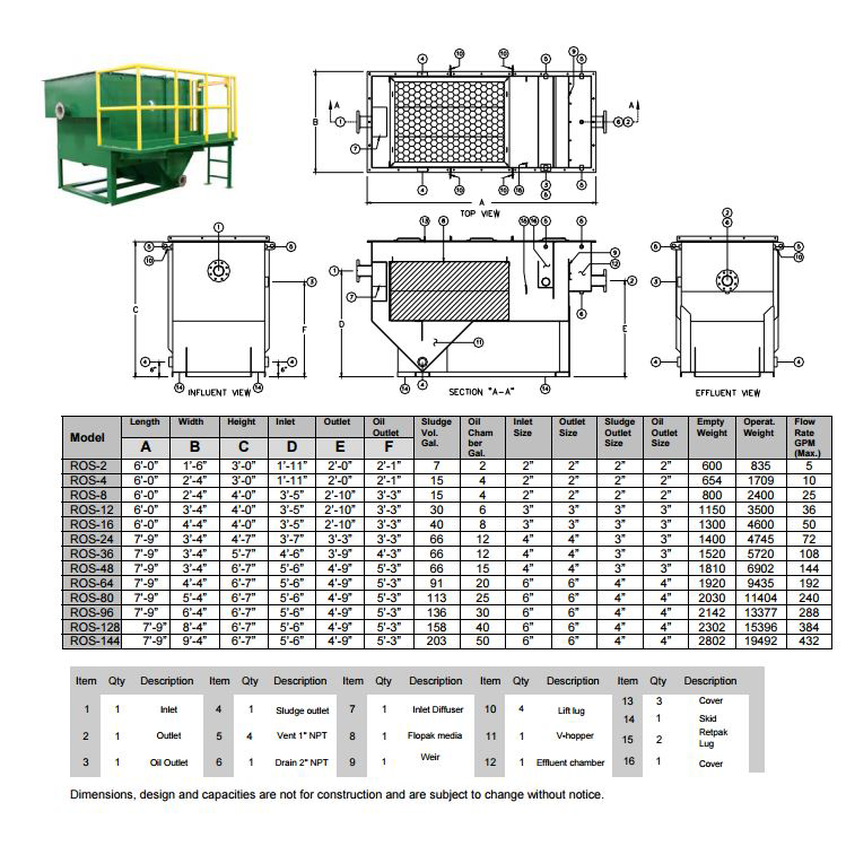

System model: Coalescing Separator

Number of model sizes: 33

Process types: Oil separation, TSS settling

Volume range offered: 5 – 5000 GPM

Design criteria: API-421, 1990 & current coalescing media design theory

Influent chamber: Influent diffuser or overflow weir

Separation chamber: To contain Flopak media pack(s)

Solids hopper: Located under and after separation chamber and TPI packs

Clean water effluent chamber: Located after separation chamber

Water baffle: Water flows over this baffle to exit tank

Weir plate: Vertically adjustable weir plate to maintain operating water level

Oil skimmer: Fixed or adjustable weir plate integrated into the oil reservoir, located in the separation chamber

Oil reservoir: Located in separation chamber for temporary storage of skimmed oils

Media pack: Single or multiple, Wave Plate or flat plate separation packs

Cover: Multiple section vapor retaining, gasketed with polyethylene gasket and attached via zinc plate fasteners

Fittings: NPT couplings up to 3″, 4″ & larger: 150# ANSI B16.5 FF flange

Base: Steel skid base of channel, beam or tube construction

Lifting lugs: (4) Minimum, located at lifting points on sidewalls of tank

Piping: A-53 black steel, 304/316 SS, FRP, PVC

Testing: Dye penetrant on steel construction

Surface preparation(steel): Interior surfaces shall be prepared to an SSPC-SP10 near white metal blast. Exterior surfaces shall be prepared to an SSPC-SP6 commercial blast.

Coatings (steel) : Interior coating shall be coated with Ameron High Build Coal Tar Epoxy Amercoat 78HB (16 mils DFT).

Exterior coating shall be coated with Ameron epoxy primer, Amerlock 2, (5-8 mils DFT). Final coat to be Ameron Amershield Aliphatic

Standards used: Polyurethane Enamel coat (5 mils DFT)Surface color to be Green RT-2203.Elements of AWS D1.1/1.1M, API, API-650, API-421, ANSI, IEC,AWS D1.6, UL, UL-508,UL-845,SSPC,ASME, CSA, NEMA, NFPA79, NEC

OIL WATER SEPARATOR THEORY

APPLICATIONS:

Contaminated ground water treatment for removal of gasoline, diesel, JP, jet fuels,

LNAPL, DNAPL, motor oils, kerosene, fuel oils and more.

Refineries

Removal of crudes, gasoline, diesel fuel, motor oils, transmission fluids,

hydraulic fluids, jet fuels, aircraft fuels from refining processes.

Vehicle Wash Racks

Removal of gasoline, diesel fuel, motor oils, transmission fluids, hydraulic fluids, jet fuels, aircraft fuels and lubricants when washing jets, cars, trucks, heavy equipment, railroad locomotives and equipment.

Military Wash Racks

Field equipment, jet wash, tracked equipment wash uses for typical fuels and oils removal. Complete treatment systems are offered. (Also see VEW systems)

Industrial Process Water

Hydraulic fluids, machining coolant/cutting fluid tramp oil removal, compressor condensate, machined parts rinse water.

Steel Mills

Rolling mill hydraulic oil/water extraction, compressor condensate, stormwater runoff, drain water.

Stormwater Treatment

Parking lot runoff, railroad re-fueling depot runoff, gas station runoff, bridge runoff.

Shipping Ballast & bilge water treatment.

Off-loading of water to shore based treatment system, bunker & diesel fuels removal.

Tank Farms

Fuel, oil storage tank farms for removal of water from tank bottoms. Stationary and mobile systems are offered.

Petro-Chemical

Refineries, chemical compounding companies, hydrocarbon based chemical bases such as cumene and other materials.

Power Generation

Generator lube oils, hydraulic oils, fuels. Stationary & mobile systems offered.

Heat Treating

Heat treating facility oily wash solution can be continuously treated.

OPTIONS

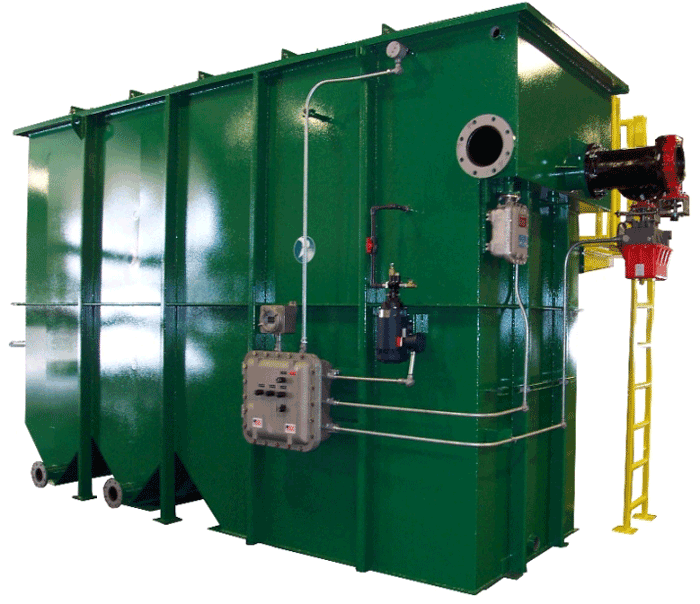

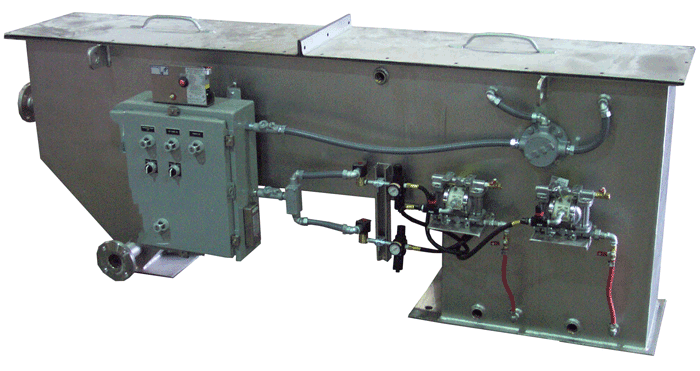

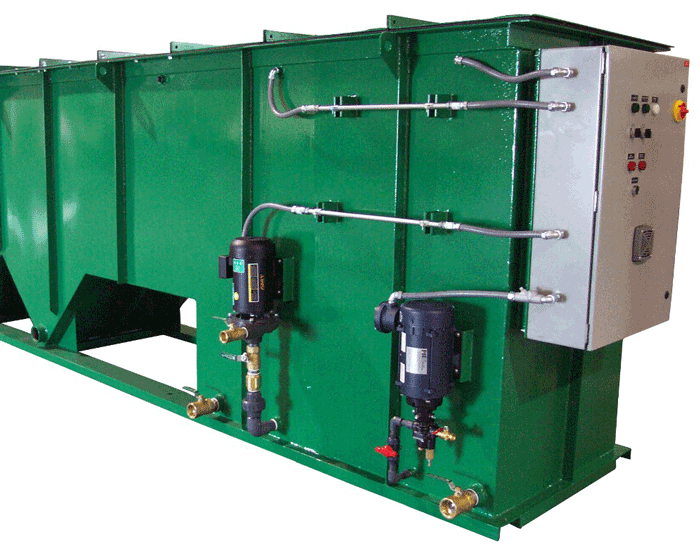

Air operated, diaphragm pump with air controls or progressive cavity pump, sump level switches & Nema 4 control panel, base mounted, 115/230/460V power offered. Electric diaphragm pumps available.

Effluent Pumpout:

Centrifugal pump with level switches & Nema 4 control panel, base mounted, 115/230/460V power offered. OS Effluent chamber must be expanded to accommodate pumpout or provision of an external pumpout tank.

Sludge Pumpout System:

Air operated, diaphragm pump with air controls & Nema 4 control panel, auto on/off timer, base mounted, 115V/1ph/60Hz power req’d. Progressive cavity pump system also available. 1 – 100 GPM.

Oil Pumpout System:

Air operated, diaphragm pump with air controls, level switches & Nema 4 control panel, base mounted, 115V/1ph/60Hz power req’d. Electric gear or progressive pump systems available. 1 – 100 GPM (larger if required)

Sludge Auger:

OS separator V-hopper(s) can be provided with a sludge auger. System consists of stainless steel shafts with coated steel screw auger(s) driven by a slow speed gear motor drive assembly. The auger extends the full length of the solids hopper(s) and conveys solids to the sludge outlet. A Nema 4 on/off control box is provided, power required: 230 or 460V/3ph/60Hz.

Freeze Protection:

Immersion heaters mounted through tank wall. Each heater has an independent thermocouple well, 0-100 deg. F thermostat and Nema 1 (or optional Nema 4) housing. 230/460V/3ph/60Hz power req’d.

Retpak Secondary Coalescer:

High surface area, reticulated, secondary coalescing media for polishing flow after standard Flopak media.

Oil Sight Glass:

Two automatic, brass valves with tempered sight glass and protection rods mounted in oil reservoir. If glass is broken check ball stops outflow from reservoir.

External Sight / Level Glass:

An externally mounted clear PVC sight tube is provided with multi-point level switch for indication or pump control of oil or water. Switch is removable for cleaning and inspection.

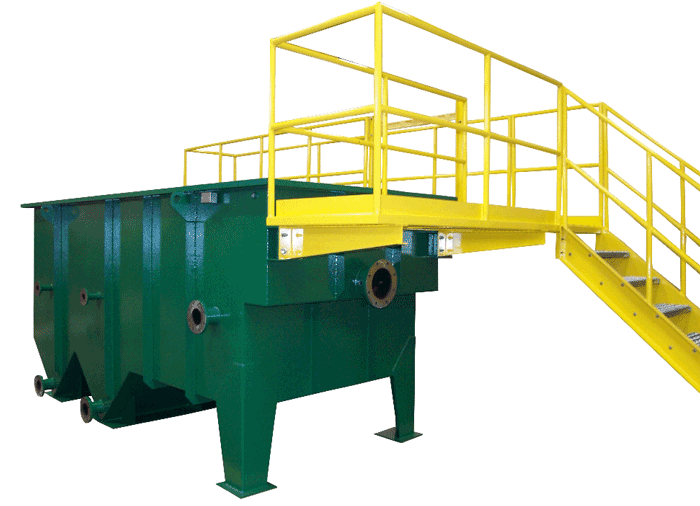

Elevation Stand:

Epoxy coated steel stand or legs to elevate tank to desired level. Standard deck height is 30″. Full platforms & walkways with ladders or stairways can be designed where required or desired.

High Temperature Design:

Flopak coalescing media and any piping is constructed of a combination of CPVC &/or polypropylene (or other materials) for temperature resistance up to 200 F.

Alternate Media Construction:

Standard Flopak media is PVC. HPVC, polypropylene, glass-coupled polypropylene and 304/316 stainless media is available. Contact SkimOIL to determine proper media type for your application. Media plate spacing is available in 1/2″, 3/4″ & 1.2″.

External Storage/Feed Tanks:

A wide variety of tank volumes can be supplied for your water, product and sludge holding needs. Flat bottom and cone bottom designs constructed in polyethylene, fiberglass, steel & stainless steel can be provided.

Effluent Filter Systems:

Solids filter systems can be provided to remove filterable solids from the separator effluent. Contact SkimOIL to determine proper filtration needs for your application.

Specialty Filter Systems:

(Alkyl Quaternary Ammonium Montmorillonite) filter systems can be provided to remove trace hydrocarbons, sheens, DNAPLs, slightly soluble chlorinated hydrocarbons and high molecular weight organics from the separator effluent. Contact SkimOIL to determine proper filtration needs for your application. Can be used to protect and increase GAC lifespan.

Carbon Filtration Systems:

GAC carbon filters can be provided to remove contaminants after the separator. Contact SkimOIL to determine proper system needs for your application.

Emulsion Cracking Systems:

Emulsion cracking systems can be provided to remove oil-in-water emulsions prior to the separator. Contact SkimOIL to determine proper system needs for your application.

pH Adjustment Systems:

pH adjustment systems can be provided to maintain pH levels prior to or after the separator. Contact SkimOIL to determine proper system needs for your application.

System Containerization:

OS separators with any options can be installed in a 20 or 40’ shipping container(s) to simplify system provision and field implementation. System would include the complete mounting, piping and wiring of the system in one or more container as required by the project.

Trailer Mounting:

OS separators can be mounted on a trailer for system mobilization. Trailer design generally includes corner leveling jacks, bubble levels, walkway, toolbox, electric or hydraulic brakes, piping and wiring of options.

Field Skid Mounting:

OS separator system can be mounted to a mobile skid with leveling for quick field mobilization.

Skid Mounted System:

OS separators can be combined with our other treatment equipment and options into a fully integrated, custom designed system completely mounted, plumbed and wired to a system skid. To simplify your need to do the wiring and plumbing on site, reducing your time frames and on site costs, we design around your requirements.

Vent Scrubber:

Separator vapors can be extracted and scrubbed prior to discharge to atmosphere to remove VOC content.

Level Sensors:

Level sensors can be provided to detect water and oil/fuels. One or more sensor points can be provided to perform various functions such as high level, low level, pump on/off based on liquid levels and level detection for DCS controls or other functions based on your needs.

Class 1 Div 1 & 2:

Systems can be designed for use in a class 1 div 1 or 2 environment. Controls, components and wiring are changed to meet the needs of these environments. Intrinsically safe relays are also used for level sensors.

Oil Monitor:

An oil detection system can be provided to monitor effluent oil content and provide various actions based on the oil alarm setpoint. Actions might include: audible/visual alarm, redirection of influent or effluent via actuated valve, shutdown of influent pump or your custom action.

Seismic Design:

The system can be designed for zone 2, 3 or 4 installations.