Coalescing Media

Replacement Media for Oil Water Separators,

CPI’s, Concrete and In Ground Separators

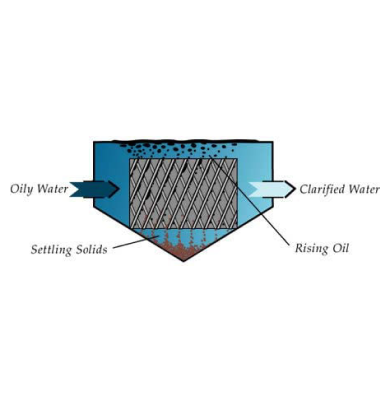

Flow-Thru coalescing media systems are designed to remove non-emulsified, free & dispersed oils and fuels from water.

Coalescing Media is a standard feature of our high performance oil water separators and are also offered for replacement or retrofitting of existing tanks to improve performance and increase flow rates. Removal efficiencies have been as low as <1 mg/L down to non-detect.

Typical, regular performance is in the 3-10 mg/L range depending on wastestream characteristics.

SkimOIL can provide review of your existing tank to replace existing media or engineer the fitting of Flow-Thru into a tank for the first time via modifications to optimize tank design for the best oil separation environment.

Coalescing Media

♦ Cross-corrugated surface design

♦ High surface area per Ft3

♦ Long lasting PVC construction

♦ Solids settling/clearing design

♦ Numerous droplet impact sites

♦ Numerous changes of flow direction

♦ Space efficient design

♦ 60° corrugation angle

♦ Stainless Steel (304/316) Media frame sets

♦ HPVC/polypropylene/stainless media construction

♦ Ret-Pak secondary coalescing media

♦ Custom shapes and sizes to meet your needs

Customization & modifications to fit your project needs are offered to convert existing tanks into our high performance design or new design/build designs tailored to your facility and application. Typical performance is 10 mg/L or less, 30 micron oil droplet.

Products removed: motor oils, fuels (vehicle/jet), fuel oils, hydraulic fluids, immiscible machining oils, lube oil, transmission fluid, bunker c, DNAPL, LNAPL, vegetable based oils, crude, air compressor lube & other hydrocarbon based derivatives (BTEX etc..). Model sizing is based on the oil/fuel specific gravity, droplet size removal desired and other parameters of the wastestream.