Waste Water Evaporators

Industrial and Commercial Marine Waste Water Evaporators

Industry is making more and more nasty waste water streams that are tough and prohibitive to treat for release, while evaporation can still be a viable alternative, despite high energy costs.

BilgeVAP—-MARINE WATER EVAPORATOR

Bilge Water, Gray Water, Treated Black Water–Zero Liquid Discharge

MarineVAP–Bilge and Gray Water Evaporator System

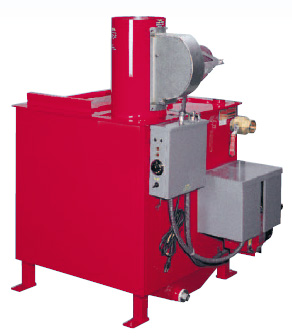

ShoreVAP—-Gas Fired Waste Water Evaporator

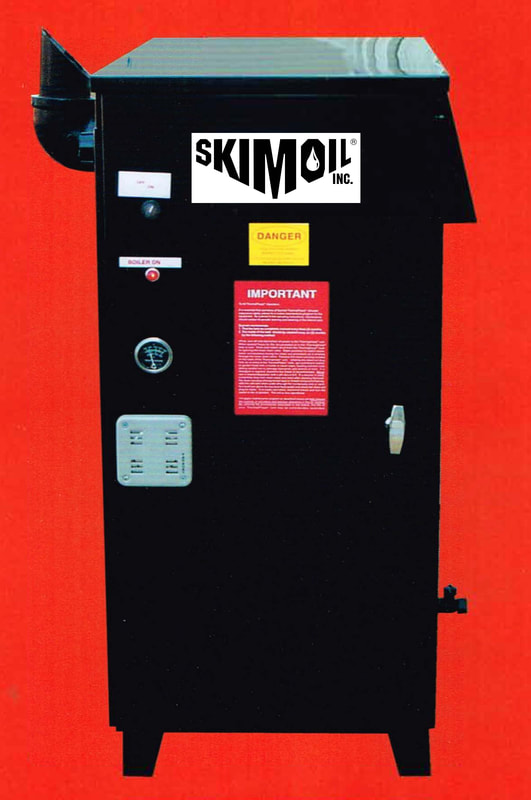

Oil Fueled EVAPORATOR—-Oil or Gas Fired Waste Water Evaporator

ConEVAP—-Waste Water & Air Compressor Condensate Oil Water Separator Evaporator

After the BilgeVAP we introduced our ShoreVAP gas powered atmospheric evaporator, used mostly for industrial waste water evaporation. At last here was an economical evaporator for industry. It’s rugged, reliable and with simple controls and few moving parts-can be used almost anywhere.

Water is water at 211 degrees and goes to vapor at 212! For brute force simple waste water evaporation, see the simple, simple -maybe even stupid ShoreVAP.

A few years back everybody on the water was simply dumping all their gray water and treated black water overboard, but our sins started catching up with us, in the form of algae blooms and dead fish. Finally the marine / maritime industry woke up and realized they were too much just dumping junk into the very water they made a living on. In 2008 the EPA was successfully sued to begin enforcement of the Clean Water Act for the marine industry. This was the birth of the Vessel General Permit (VGP) that is now dead having morphed into SubChaper M, and the beginning of the end of just dumping all your water overboard.

Enter the MarineVAP, our next generation, automatic smart evaporator system that handles and evaporates all the onboard waste waters-and does it clean and neat. MarineVAP is electric powered and comes in 7 sizes up to 25 gallons per hour evaporation rate. This new MarineVAP is loaded with redundant safety shutoffs and thermostats and plenty of monitoring / control points. This is an evaporator that you can put on auto-pilot on a boat or in a Nuke plant or —-maybe your place.

Got water? How about ZERO LIQUID DISCHARGE?

We saved the best for last here. Our OilEaterVAP is an oil (or gas) fired evaporator, that can run on diesel or fuel oil-AND can have an auxiliary burner that can run on natural gas/propane or even waste oil (or the opposite). The OilEaterVAP will deliver between 15 and 20 gallons of evaporation for every gallon of oil burned……..and you can use it to get rid of used/waste oils. This is a serious evaporator—-designed by a genius engineer STATE OF THE ART.

For industries that create a lot of waste oil or have water contaminated fuel—this could be several solutions—-to several problems. Consider you can use oil or natural gas as a primary fuel..and supplement that with Evaporate your water away!. Get rid of your waste oil. ZLD in it’s best form.