The MSD Tank

USCG and IMO Certified Type ll Marine Sanitation Device

Black and Gray Water Treatment System

Application Survey

S/LX/X Series Brochure

S/M/X and S/MX/X Series Brochure

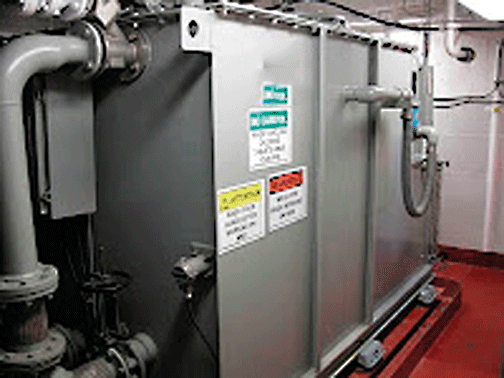

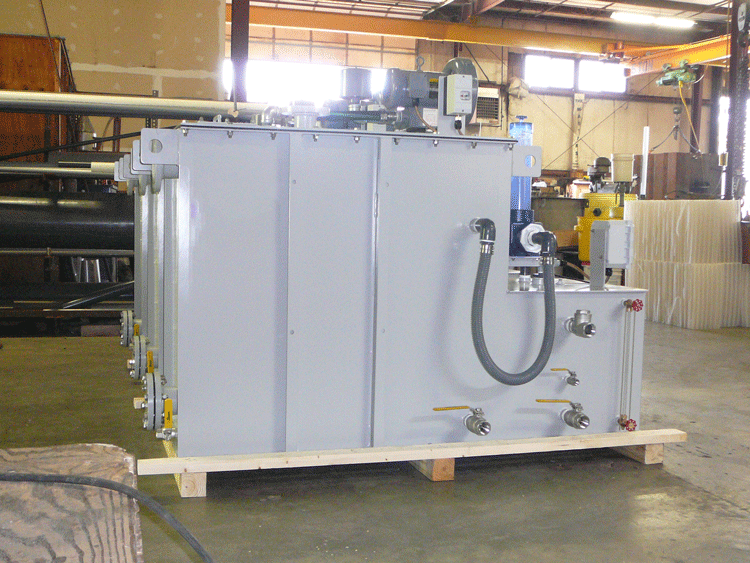

Ready to fit and work in limited spaces, the MSD system is a complete package ready to install and operate. For ALL VESSELS:

- Dredges

- Towboats

- Offshore Platforms

- Tankers

- Harbor Tugs

- Tugs

- OSV’s

- Pilot Boats

- Line Boats

- Drill Ships

- Cruise Ships

- Float homes or camos

Media Tank and Wetwell, Aeration Blower, Tablet Chlorinator, Effluent Discharge Pump and Manual motor starters and controls

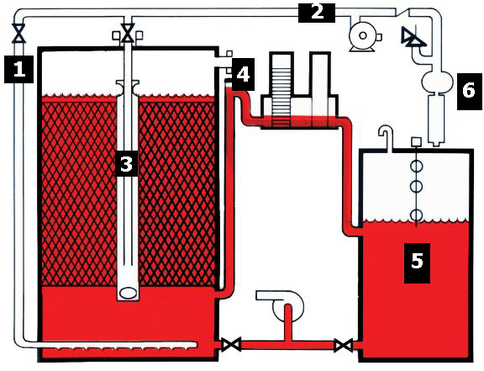

How It Works! The MSD starts off full of water and bacteria.

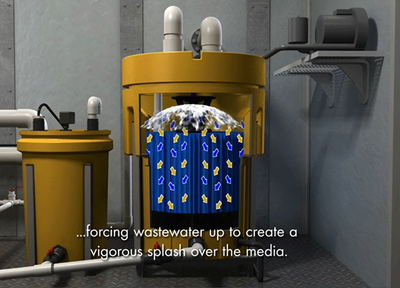

#2. The Quiet compact blower provides air (for the aerobic bacteria) thru internal piping for the airlift system in the media tank.

#3. The Aeration blower pump thru the airlift circulates and aerates the hungry bacteria promoting growth to build and populate the media as a base to work from to eats and digest the organic. material (poop & paper).

These bugs love POOP!

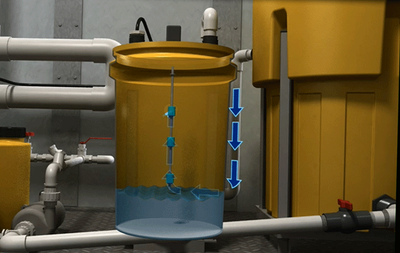

#4 The digested and treated effluent / black water flows into the chlorine contact chamber or wetwell, over the tablets to dissolve the chlorine in the right portion for disinfected discharge. Options available

#5. Sized for peak flow periods the chlorine chamber or Wetwell provides adequate time to disinfect the effluent prior to discharge. Automatic float switches control water levels for on/off operation.

#6. A built in submerged effluent pump in the wet well pumps treated effluent.

EFFLUENT STANDARDS:

USCG 33CFR159 – Minimum 33CFR159 / MEPC.2(VI) standards for 150; TSS, 200 fecal, certifi ed by U.S. Coast Guard installed aboard vessels and not subject to effluent sampling in service not required by regulations.

So why get The MarineFAST MSD?

A Marine Sanitation Device (MSD) is required on all vessel with toilets. Even with lots of movement on the water, small spaces to work with, variable crewing and flow surges, The MSD’s robust design and treatment process delivers on the consistent performance to make the MSD extraordinarily reliable.

The MSDTank is self regulating and no adjustments are needed—ever. Surge loads at shift changes and with other activities don’t affect performance. The MSD is not reliant on operator intervention or skill. This is a simple reliable technology married to high quality components with tight quality control insuring great performance even under tough conditions. The MSDTank takes all the crap you can give it!

The MSD Tank System meets and exceeds standards for USCG 33 CFR Part 159 Certification, including design, construction, and testing. The Type ll MSD system is an aerobic/biological digestion based, flow-through discharge service, producing effluent having fecal coliform bacteria count not greater than 200 per 100 Milliliters and suspended solids not greater than 150 Milligrams per liter.

Here's what you get!

- Certfied, reliable and well proven technology

- Strong, custom steel tanks

- Smaller vessel systems in HDPE and XLPE tanks

- Corrosion Proof

- Custom or standard designs

- Self starting and self regulating operation

- Longer Service life