Oil Content Monitors

BilgMon 488 and TPH Monitors for Industrial and Commercial Marine Oil Water Separator

An Oil content monitor is a device for real time sampling and measuring of the oil content in a moving stream of water. The new IMO/MEPC 107 (49) oil content monitors for oil water separators perform several functions including preventing illegal “over limits” discharges that occur when the oil content is above 15 ppm, by either shutting down the separator or by putting the separator into a recirculation or recycle mode———where the oily bilge water is sent back to the oily wastes holding tanks.

These newer monitors also have the ability to alarm the operator with audible and visual alerts as well as having dry contacts out that can be wired into a ship’s or oil platforms main controls systems.

At SkimOil we use oil content monitors on our BRUTE marine oil water separators, Bilge Filters and for industrial process measurement purposes. Our marine oil water separators can be USCG/ABS/BV certified only when they use an approved monitor.

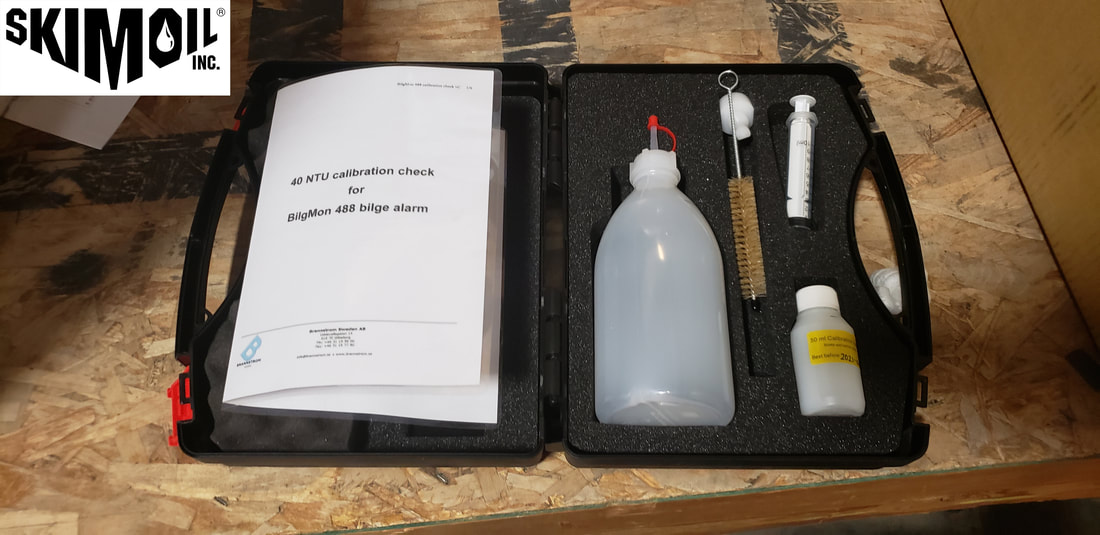

These oil content monitors are our default monitor for our BRUTE OWS and bilge filter and come with a 5 year certification which means it is certified to meet IMO/MEPC 107 (49) requirements for 5 years——-as long as the seal on the unit is not broken or missing. After 5 years it has to be re-calibrated to be certified as compliant with regulations. Big trouble awaits you if your monitor is out of certification because you would then be out of compliance with IMO/MEPC 107 (49) requirements and operating illegally. While there are a few recalibration services around, doing that takes you out of operation. The solution or work-around for that is simply getting a new measuring cell and simply installing it on your oil content monitor and you are then instantly recertified for another 5 years——-as long as you don’t break the seal on the measuring cell. It’s a simple quick installation and you’re back in business and back to being certified. Contact us directly for a certified replacement measuring cell.

>>>Click here for a BilgMon 488 Brochure

>>>Equipment: Regulations for Service & BilgMon Calibration

>>>click here for a Smart Cell brochure

>>>click here for a Smart Cell brochure

For the marine/maritime industries we can even furnish these SAMS with oil content monitors for ships, drilling rigs, wells, O&G exploration and even on moon pool skimming jobs. These units are compliant with IMO/MEPC 107 (49) regulations and meet all USCG/ABS/CE/BV requirements. This is pretty much a world wide standard for the marine and offshore

petro operators.

WORLD CLASS EQUIPMENT

Need special controls or monitoring ? Need to monitor fluid conditions real time? Can do.

Ph, TDS, TSS? chlorides, phosphates etc etc What do you want to monitor?

Bottom LINE on real time sampling:

SAMS can be built to your specs, to include dedicated feed pumps and several levels of explosion proof XP enclosures and controls. These SAM systems can be mounted on their own stand and/or rack/bulkhead mounted. Let’s chat this up, give SkimOIL a call!